Metalworking Machines

Fibrolaser systems - BRILASE

Fiber laser cutting machines are machines used for laser cutting. Durmazlar designed, developed, produced and introduced to the world market the first optical laser power supply system in Turkey, BRILASE ©. Thanks to the superior beam quality; fiber lasers are the first choice for precision cutting and marking applications. Durmazlar machines equipped with the BRILASE system offer high-quality production with exceptional beam quality, precision, speed and ease of use. In the BRILSE system, the laser beam to be used for cutting is generated in the laser power unit. The beams formed in the modules of the Durma BRILASE module are easily transported to the cutting head without loss via an optical cable.

With its expanded product range with BRILASE, Durmazlar has once again set industry standards in laser manufacturing.What are the advantages of the BRILASE optical-laser system?

1. User friendlyDurma Fiber Laser Systems - BRILASE are user friendly. Automatic workflow saves your time. It is also easy to use thanks to its ergonomic design. BRILASE provides ease of use for operators as well as continuous operation to meet the production requirements of users even under harsh industrial conditions and heavy loads.

2. Energy-savingBRILASE fiber laser cutting system saves energy. Its advanced technology and design are perfect for saving energy. Advanced Stop technology is specially designed to ensure that your system saves energy. In addition, your machine allows you to save both on electricity bills and time and labor.

3. They are produced reliably, Durma's state-of-the-art technological products to ensure precise results. Durma BRILASE is a durable, reliable and long-lasting system. Plus, this reliable system delivers reliable results every time.

4. ExclusiveMost products on the market for industrial laser processing cannot even provide less than 10% of the maximum power. BRILASE outputs up to 60 W and provides very good laser marking.

Why should you choose Durmazlar?

Work, like life, is a journey. With Durmazlar machines, you will overcome all obstacles and overcome all difficulties. We will be with you every step of the way regarding your business. We know that your growth is our growth, your success is our success. As Durmazlar, we produce durable, flexible and innovative machines. We strive for perfection in all our machines and attach importance to our communication with our customers to produce perfect machines. Our cutting-edge products give you fast and perfectly clear results.You will continuously progress, develop and produce with Durmazlar.

HD-TC laser machine for cutting pipes and profiles

The fiber laser cutting machine is used for cutting pipes and profiles. Laser pipe cutting is specially designed for enterprises that value high-quality pipes (maximum diameter 220 mm) and profile cutting. The Durma HD-TC laser profile and tube cutting machine cuts tubes and profile materials with a thickness of 0.8 mm to 10 mm using a laser cutting power of up to 3 kW.

Fully automatic loading and unloading requires less operator effort and saves time. The movable axes operate with maintenance-free, dynamic and high-performance AC servo motors. In addition, a suction system is used to suck the dust generated during laser cutting into the dust collection filter.

This machine is best suited for business areas that require automatic execution of various operations. With the HD-TC laser cutting machine for pipe profiles, operations such as drilling and cutting are performed in a short time. Many sectors such as automotive, furniture, racking systems, machine manufacturing, construction, agricultural machinery and steel structures can use HD-TC lasers. The use of pipes and profiles is common in many business areas. These; power lines, telecommunications and agricultural machinery. Pipes and profiles are also used in steel structures, automotive, furniture and machine manufacturing.

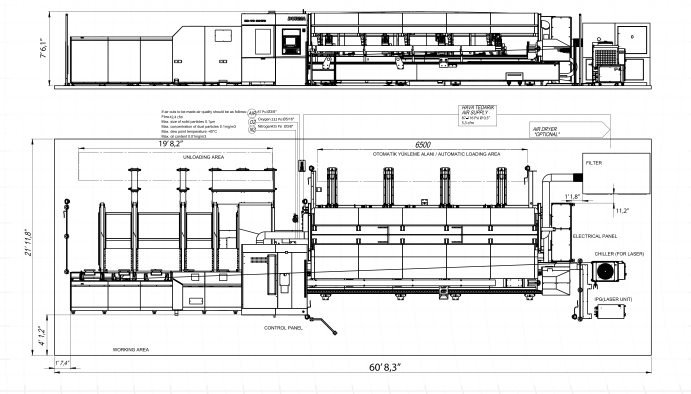

Dimensions of a 6 meter machine

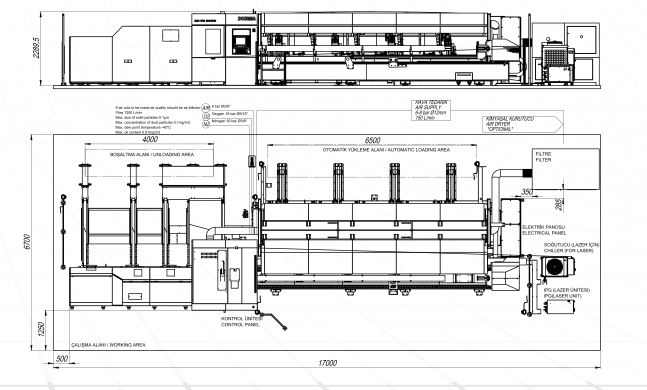

Dimensions of a 4 meter machine

What are the advantages of HD-TC laser and pipe profile cutting machine?

HD-TC is best suited for business areas that require automatic execution of various operations. With the HD-TC laser cutting machine for pipe profiles, operations such as drilling and cutting are performed in a short time. Many sectors such as automotive, furniture, racking systems, machine manufacturing, construction, agricultural machinery and steel structures can use HD-TC lasers. Operations like cutting various geometric shapes can be easily done with this machine.

Most applications strive for high levels of precision in such processes. It is clear that the application of laser technology in cutting pipe profiles will create an opportunity for aesthetic and flexible design. In addition, HD-TC lasers offer high speed in production as well as in sheet metal cutting.

Convenient to use Durma HD-TC profile laser cutting machine is specially designed to be easy to use. Automated workflow will save you time. In addition, this machine provides ease of use thanks to its ergonomic design.

1.Energy-saving Durma HD-TC profile laser cutting machine is designed to save energy. Its advanced technology and design are ideal for saving space and energy. As Durmazlar, we know you need an efficient and easy-to-use machine. The HD-TC Laser is a fast, ergonomic and easy-to-use machine. If this machine meets your needs, this is the right choice for you. Advanced Durmazlar technology is specially designed to ensure that your machine has low operating costs. Your machine will save you electricity bills, time and labor.

2 Made with reliable Son Durmazlar technology, this machine is manufactured to provide precise results. Durma HD-TC machine for laser and profile cutting of pipes is a durable, reliable and long-lasting machine. Its flawless technology will ensure reliable results every time. Why should you choose Durmazlar?Work, like life, is a journey. With Durmazlar machines, you will overcome all obstacles and overcome all difficulties. We will be with you every step of the way regarding your business. We know that your growth is our growth, your success is our success. As Durmazlar, we produce durable, flexible and innovative machines. We strive for perfection in all our machines and attach importance to our communication with our customers to produce perfect machines. Our cutting-edge products give you fast and perfectly clear results.

Technical specifications

Maximum pipe size Ф 220mm

Maximum size of the square profile 160x160 mm

Maximum size of the rectangular profile 200x100 mm

Minimum pipe diameter Ф20mm

Maximum profile length 6500/8500

Minimum autoload profile length

Maximum profile weight kg/m 37.5kg

Maximum thickness for 2kw 8mm

Minimum thickness for 2kw 0.8mm

Autoload- Yes

Automatic unloading -Yes

Cutting head-

Mirrors 2D-1 piece

|

|

|

|

|

|

|

|

|

|

|

|

|

Centering mirror Yes |

Centering mirror Yes |

|

Length of the last detail 145mm |

Length of the last detail 145mm |

|

Linear speed of the mirror m/min 60 |

Linear speed of the mirror m/min 60 |

|

Linear acceleration of the mirror m/s2 10 |

Linear acceleration of the mirror m/s2 10 |

|

Accuracy +_0.20mm |

Accuracy +_0.20mm |

|

Repeat accuracy +_ 0.05mm |

Repeat accuracy +_ 0.05mm |

|

Types of profiles Round, Square, Rectangular, Ellipse |

Types of profiles Round, Square, Rectangular, Ellipse |

|

Open profile types C,U,L |

Open profile types C,U,L |

|

Centering mirror Yes |

Centering mirror Yes |

HD-F COMBI 2D for cutting straight pipes and profiles

Pipe - Profile Cutting

Technical Characteristics

Hd-f 3015 & Hd-f 4020 & Hd-f 6020

Maximum Pipe Diameter 170mm

Maximum Square Size 120x120mm

Maximum Profile Size 150x100mm

Minimum Pipe Size 20mm

Maximum Length of the Material 6500mm

Maximum Length for Automatic Unloading 4500mm

Maximum Length for Manual Unloading 6000mm

Maximum Weight 37.5kg/m

Maximum Total Weight of the Material 210 Kg

Cutting Accuracy +_0.2mm

*Hd-f 6200 for 6500mm

***The Maximum Accuracy of Cutting the Workpiece Depends on the Type of Profile and the Method of Production

Hd-fl Laser Cutting Machinedurma Hd-fl Laser Cutting Machines Are Fast Machines. The Hd-fl Laser Cutting Machine Is Distinguished by Its Fast Cutting Functions. In Addition, Quality, Performance and Efficiency Are Guaranteed. The Movements of the Axes Are Carried out with State-of-the-art Linear Motors, Which Can Reach Very High Values Of Acceleration and Movement Speed. Linear Motors Achieve Very High Acceleration (Max. 35 M/s2), Flexible Travel Speed (Synchronous 280 M/min.) And World-class Positioning Tolerance (±0.03 Mm).

What Are the Advantages of Hd-fl Laser Cutting Machine?

1. User Friendlythe Hd-fl Laser Cutting Machine Is Specially Designed to Be User-friendly. Automated Workflow Helps save Time. It Also Provides Ease of Use Thanks to Its Ergonomic Design.

2. Energy Savingthe Hd-fl Laser Cutting Machine Is Designed to save Energy. Its Advanced Technology and Design Are Ideal for Saving Space and Energy. As Durmazlar, We Know You Need an Efficient and Easy-to-use Laser Cutting Machine. If You Are Looking for a Fast, Ergonomic and Easy to Use Machine, This Is the Machine for You. Advanced Durmazlar Technology Is Specially Designed to Ensure That Your Machine Has Low Costs. Your Machine Allows You to save Both on Electricity Bills and Time and Labor

3. Fastwe Know How Important Time Is in Manufacturing and That Saving Time Means More Revenue. We Designed the Durmazlar Hd-fl Laser Cutting Machine to save Time in Your Production Process. Advanced Durmazlar Technology Offers Faster and More Reliable Results. The Hd-fl Laser Cutting Machine Is Designed to Be Fast and Efficient. Axis Movements Are Performed by State-of-the-art Servo Linear Motors That Can Reach High Speeds and Accelerations.

4. Reliablethe Latest Durmazlar Technological Products Are Produced to Ensure Perfect Results. The Hd-fl Laser Cutting Machine Is a Durable and Reliable Machine. All Frictionless Linear Motors Used in the Machine Are Water Cooled. Temperature Controls Are Driven by a Heatsink Independent of the Cutting Head and Laser Power. In This Way, the Machine's Linear Motors Run Trouble-free for Years.

Hd-f / Hd-fl 3015 4020 6020 8020 12020 Mm

Xoc 3060 4100 6150 8200 12200

Y Oc 1530 2100 2100 2100 2100

Z Oc 160 185 185 185 185

Max. Sheet Size 3048x1524 4064x2032 6096x2032 8128x2032 12192x2032

Max. Sheet Weight 315 315 315 315 315 Kg/2

With Depot Hd-f Line System Hd-fl 3015

X Oc 120 160 M/min

Y Oc 120 160 M/min

Synchronization 170 226 M/min

Acceleration +_0.05 +_0.03 Mm

Accuracy +_0.05 +_0.03 Mm

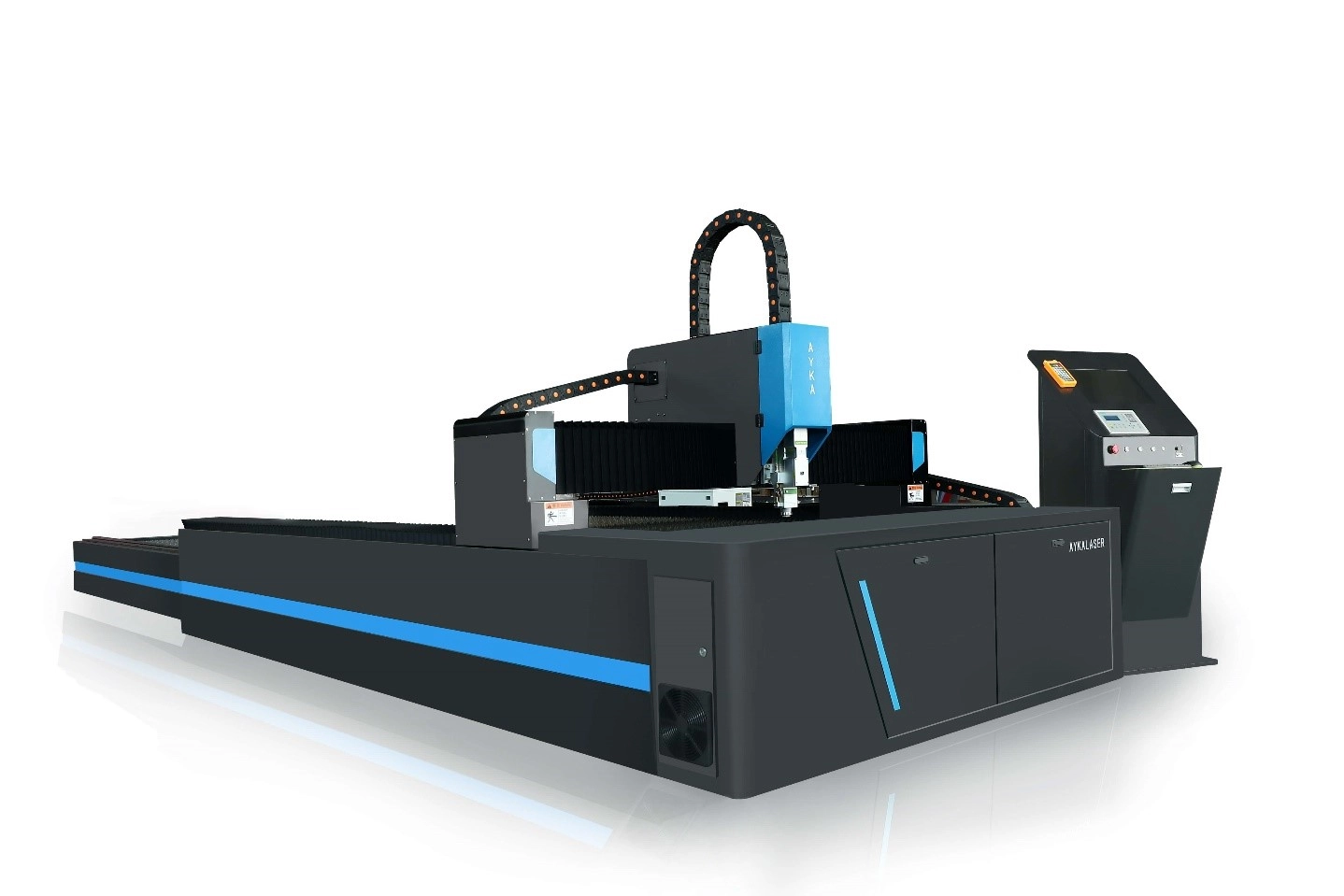

AYKA LASER- Fibro Laser 2000W

Technical specification

Model: Laser cutting and engraving

Laser type: Optical laser

Applicable material: Metal, KRABS 1500*3000mm 2000w fiber laser cutting machine

Cutting thickness: 0-3 mm

Cutting area: 1500*3000 mm

Cutting speed: 25m/min

Cooling mode: Water cooling - 6300Control software: Cypcut

Supported graphic format: AI, BMP, DST, DXF, DXP, PLT,

Place of origin: Turkey

Brand: Ayka KRABS LASER

Model number: fix-2000

Certification: CE, ISO,

Laser power: 2000W

Laser tube: Raycus

Type: Fiber laser cutting

Function: Cutting metal materials

Working area: 1500mmX3000mm

Color: Blue-white

Warranty: 2 YEARS

Working area (L*W) 3000mm×1500mm

Laser tube: 1000W

Raycus fiber laser tube

X, Y, Z axis range: 3025 mm / 1525 mm / 100 mm

Material thickness: 0.1-2.8mm (depending on the material)

Maximum cutting thickness: 8mm-10mm

Positioning accuracy: 0.03mm

Maximum travel speed: 60 m/min in a straight line

Own weight: 1500kg

Operating temperature: 0 ℃ -40 ℃

Control system: MPC6595

Maximum load per bench: 1900 kg

Drive type X, Y axis: import servo drive (Panasonic, Japan)

Drive mode: TBI roller screw

Machine size (L*W*H): 4300*2000*1300 mm

Fibro Laser 3000W

Model: Laser cutting and engraving

Laser type: Optical laser

Applicable material: Metal, KRABS 1500*3000mm 2000w fiber laser cutting machine

Cutting thickness: 0-3 mm

Cutting area: 1500*3000 mm

Cutting speed: 25m/min

Cooling mode: Water cooling - 6300

Control software: Cypcut

Supported graphic format: AI, BMP, DST, DXF, DXP, PLT,

Place of origin: Turkey

Brand: Ayka KRABS LASER

Model number: fix-3000

Certification: CE, ISO,

Laser power: 2000W

Laser tube: Raycus

Type: Fiber laser cutting

Function: Cutting metal materials

Working area: 1500mmX3000mm

Color: Blue-white

Warranty: 2 YEARS

Working area (L*W) 3000mm×1500mm

Laser tube: 3000W Raycus fiber laser tube

X, Y, Z axis range: 3025 mm / 1525 mm / 100 mm

Material thickness: 0.1-2.8mm (depending on the material)

Maximum cutting thickness: 8mm-10mm

Positioning accuracy: 0.03mm

Maximum travel speed: 60 m/min in a straight line

Own weight: 1500kg

Operating temperature: 0 ℃ -40 ℃

Control system: MPC6595

Maximum load per bench: 1900 kg

Drive type X, Y axis: import servo drive (Panasonic, Japan)

Drive mode: TBI roller screw

Machine size (L*W*H): 4300*2000*1300 mm